The Library of Lumber

Technically all libraries are full of slices of trees.

When selecting wood for your project the options are nearly endless. However I’ve developed a library of samples of common (and some not so common) woods that will work in a variety of projects.

Domestic woods

Domestic hardwoods are native to North America or have been brought here to be farmed for the U.S. market. In general these will be familiar and common woods and trees you’ve likely seen in person just walking around your neighborhood. Because of this the cost on these woods tends to be lower than exotic woods from further away. Unless you have very specific needs these are the woods I’d recommend you consider first.

Ash

$

Creamy white with gorgeous cathedral grain patterns. Perfect for those that want a light wood to fit a Scandinavian style or something with more interesting grain that maple.

Beech

$

Light tan with extremely tight grain. Primarily found in Europe but also grown in North America. A gorgeous wood that minimizes grain look while still maintaining a natural wood look

Cherry

$

Light and rosy when first cut, will darken with time and exposure to sunlight to a deep rich red, and given enough time continue to a nearly mahogany color. A staple of North American heritage furniture for a reason.

Maple

$

Bright white with tight, sometimes dark, grain. One of the most prevalent woods in north America. Strong and fine textured, a great accent when used with darker woods.

Walnut

$$$

Rich deep brown heartwood with sapwood that ranges from light tan to creamy white. Arguably the King of the domestic hardwoods.

White Oak (Quarter Sawn)

$$

Long straight grain and light straw in color with radial flecks across the grain. One of the few North American woods that is well suited for outdoor use.

Exotic Hardwoods

Native to Central and South America, Africa, and all corners of the world, exotic woods are a great choice for when you want to make a real statement. The distance these woods have to travel may mean that the price is somewhat higher, but the unique grains available just can’t be found in North American lumber and justify the cost.

Beli

$$

Straight grain with alternating dark and light stripes. Offers a similar look to Zebrawood but with somewhat less contrast between light and dark.

Bocote

$$$$

Swirling dark grain against a yellow/brown background.

Bubinga

$$$$

Deep red with tight grain. With a color somewhat close to rosewood it has become a favorite of guitar builders in recent years.

Iroko

$$

Sometimes called “African Teak” Iroko is actually a fantastic substitute for genuine teak due to it’s tight grain, very good weather durability, and insect resistance. An excellent choice for outdoor use.

Lacewood

$$$

Reddish brown in color with flecking that gives this wood its name. Grain varies greatly from board to board so best used in small pieces or as an accent on something larger.

Monterillo (Rosewood)

$$$

Extremely hard and dense with variegated coloring from dark brown to golden. A beautiful substitute for “true” rosewood without import restrictions.

Purpleheart

$$$

Deep purple in color with tight grain. Will eventually age to a rich brown with purple undertones.

Sapele

$$

Very even golden brown tone with fantastic depth and shimmer. Reasonably weather durable and can sometimes be used as a substitute for mahogany.

Shedua

$$$$

Ginger color with darker grain sometimes nearing black. A perfect wood for when you want to make a statement.

Tigerwood

$$

The dark brown streaks on the orange brown wood lend this wood it’s name. Very dense and almost waxy feeling this wood is a good option for outdoor use where you want a little more variable color.

What about Rubberwood, Eucalyptus, or Acacia?

If you’ve shopped online for wooden furniture in the last 5-10 years you’ve probably noticed that a lot of the furniture sold there is made from some combination of Acacia, Eucalyptus, Rubberwood, or some other wood not listed here.

That’s because those trees are native to areas closer to where the furniture is being made and assembled. Rather than ship containers of North American hardwoods overseas to be made into furniture, they just use the more locally available raw materials and then ship the finished products here. While there’s nothing inherently wrong with these woods, they’re not good options for building with here in the States. The high demand for them in the industrial furniture trade means that they very rarely arrive here in North America as raw materials and as such are usually more costly than domestic lumber with similar qualities.

If you’ve found something online you like the look of that lists one of these woods as the main material, don’t focus on the name. Instead look at what the wood looks like, and try to find a match from one of the woods listed here.

The Custom Build Experience

What to expect when you’re expecting (a new piece of furniture)

Getting furniture custom built just for you can be intimidating. You’ve got more options than you’re used to when walking into your local furniture store, and that can feel overwhelming. But it doesn’t have to be! I try to break it down into 3 steps, and luckily for you the 3rd one is all my responsibility.

Step 1:

Whatever your inspiration, Share it!

Anything from a 75 image Pinterest board to a scribble on a napkin.

It all begins with you and your idea. Maybe you you saw something in a shop that sparked your interest, or have an existing piece that you just can’t find a match for, even just the a general idea for a space in your home that needs something special to fill it. Tell me about it! Pintrest boards, Magazine Clippings, even scribbles on a napkin will all help me make sure you get exactly what you’re after.

Step 2:

Lets get specific!

A few simple dimensions and choices of wood are all it takes to get started. And if you prefer I can do this for you.

Once we know what we’re trying to build it’s time to get down a few of the details. If you already know what size you’re looking for and the type of wood then great! If not that’s OK, I’m here to walk you through it. A few key measurements and photos of your space are usually all I need to help you decide. But if you prefer I’m happy to schedule an in person visit where I can get everything I need myself and go over options with you in person.

Now that all the hard work is done I’ll take everything we discussed and put it together into a design that is tailored specifically for you. Don’t be afraid to change your mind! Just because something sounded good in words doesn’t mean you are stuck with it once you can see it.

Step 3:

Time to build!

Now you get to relax and watch the process.

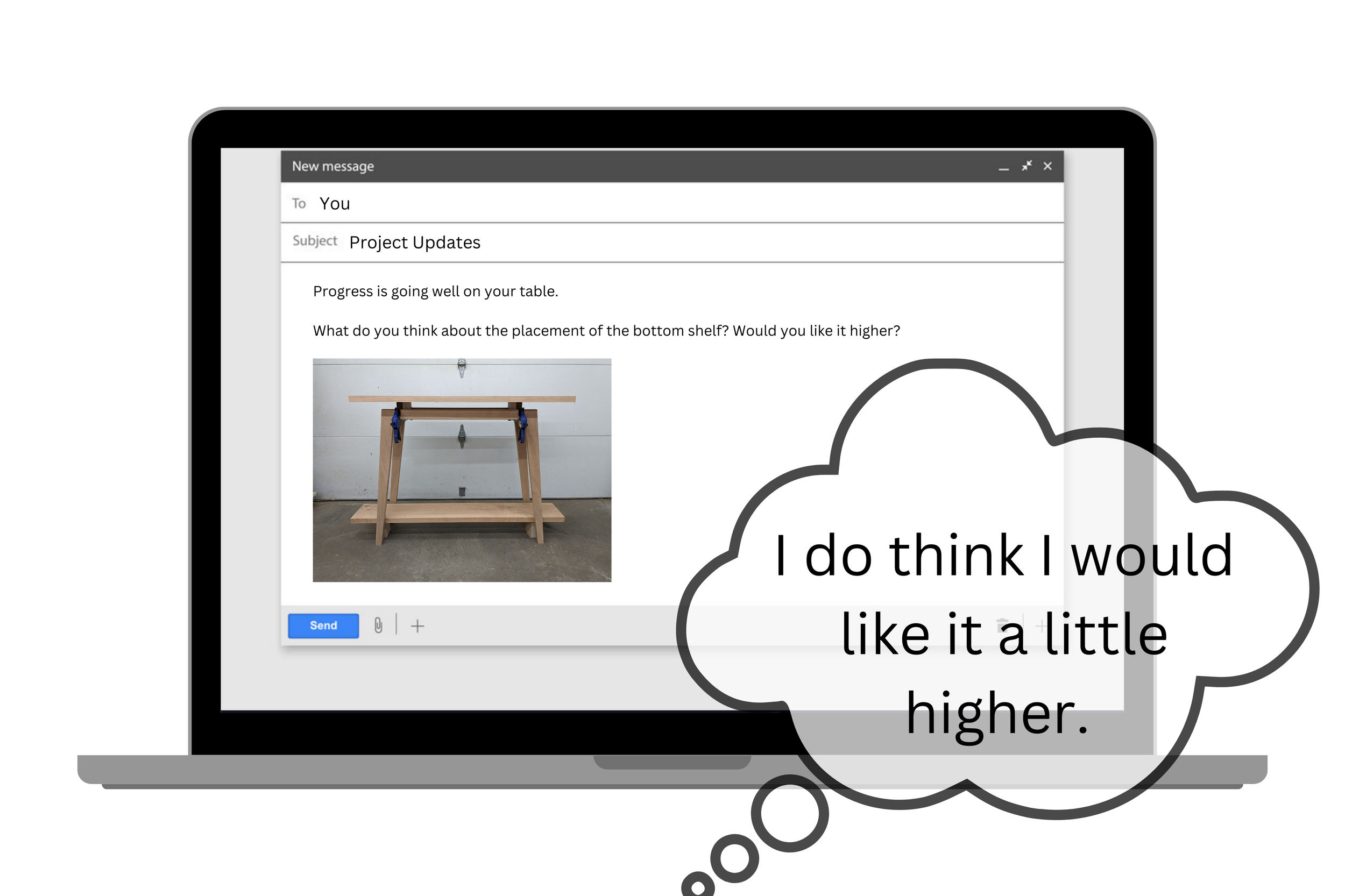

Once you’ve signed off on your design it’s time for me to build. I’ll send you occasional updates on the progress as the work goes from rough lumber to your finished piece. I may also reach out during this time to ask a question or two just to make sure we’re getting you your perfect end result. Don’t overthink it. If your gut says we should go one way or the other then follow that instinct.

That’s It! You did it!

Congrats you did it! Your new piece is ready for you to take home and brag to all your friends about!